Comprehensive Packaging Box Manufacturing Capability

Production Capability

As a professional packaging box manufacturer, we have a strong production capacity to mass-produce customized packaging boxes to meet orders with different needs. Multiple production lines and advanced equipment ensure an efficient and precise production process.

- 8000 Square Meters of Floor Space

- 10+ Production Lines

- About 10-12 Machines Per Production Line

- Annual Production Capacity of 20 Million

- Customization Flexibility

Well-established Industry Chain

As a packaging box supplier, we cover a wide range of processes from raw material sourcing, design, and production to final delivery. Yisheng has the complete industry chain capability to provide customers with a full range of customized packaging box solutions.

- Professional Design and Development

- Multiple Styles of Packaging Boxes

- Complete Production Equipment

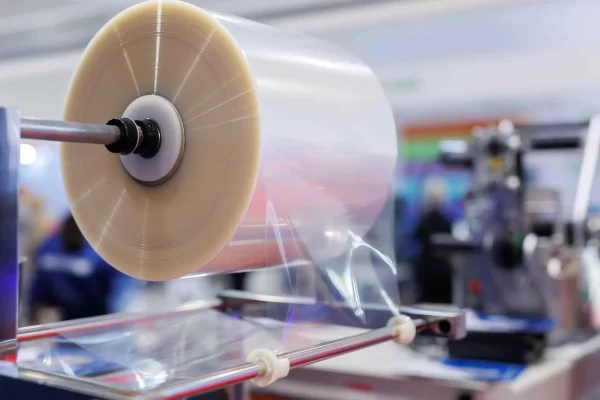

- PET, PVC, Various Paper Material

- Strict Quality Inspection

- After-sales Service

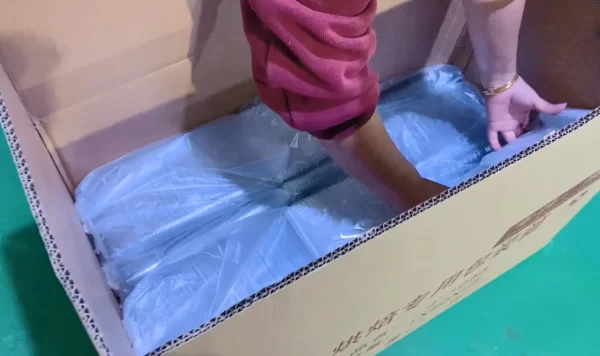

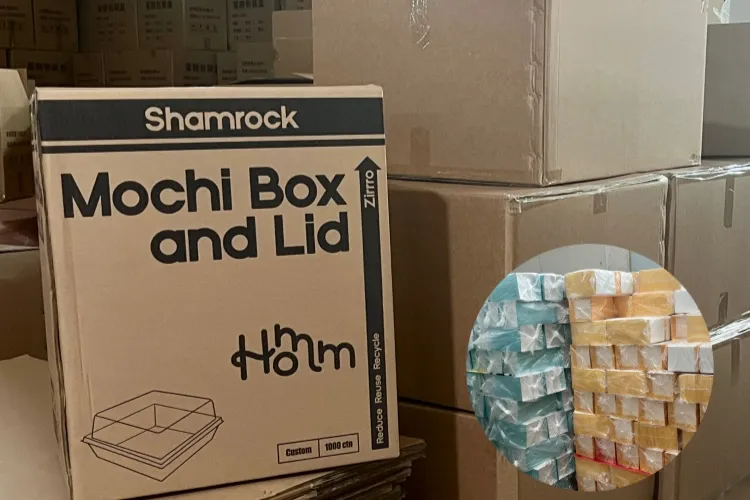

In-Stock Supply Capability

We are a packaging box factory with abundant stock to respond quickly to our customers to meet their urgent needs and short-term orders, enjoying efficient and flexible stock services to help you quickly respond to fluctuations in market demand and ensure rapid business growth.

- Fast Shipping Within 3-5 Days

- 200+ Stock Models Available

- 4000+ m2 Warehouse In Stock

- Flexible Ordering

Leading Packaging Box Supplier

Production Process of Paper Packaging Box

Raw Material Preparation

Design Plate Making

Printing

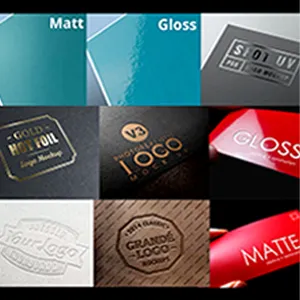

Surface Finishing

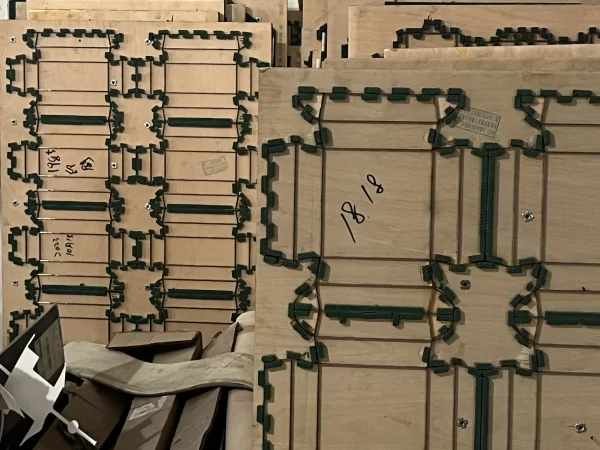

Die-cutting

Folding Molding

Quality Inspection

Storage Packing

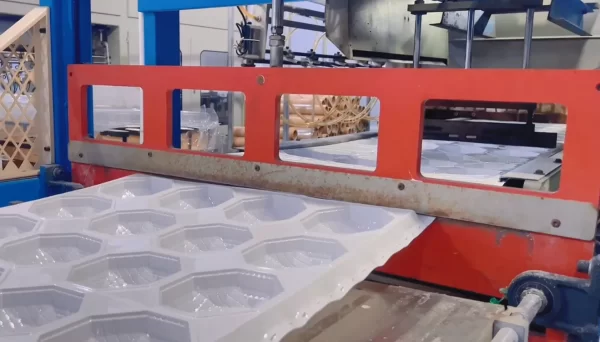

Production Process of Plastic Packaging Box

Preparation of Plastic Sheet Materials

Mould design

Heat and Soften

Blister moulding

Cooling and Curing

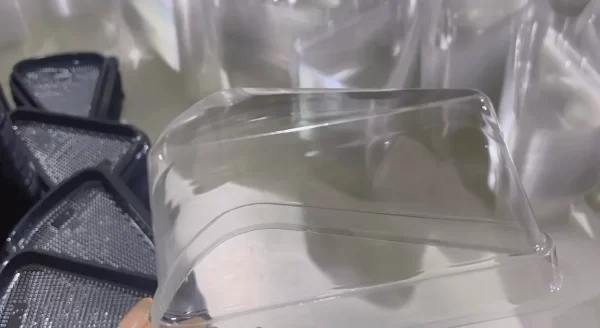

Demolding and Trimming

Quality Check