One-stop Solution for Custom Packaging Boxes

Yisheng: Your Custom Packaging Boxes Specialist

Our custom service is supported by advanced production facilities and a skilled technical team. Our custom product boxes are widely used in the bakery industry, food industry and high-end gift packaging, guaranteeing that each box meets your brand image and market needs.

Extensive Custom Packaging Box Options

Types of Materials for Customized Packaging Boxes

We offer you a wide choice of high-quality materials, customized according to product characteristics, brand positioning and environmental needs.

PET: Clear and tough, suitable for food and high-end gift packaging where content needs to be displayed.

PVC: Highly transparent, suitable for fine displays and enhancing the luxury of packaging.

White cardboard: Smooth surface and bright colors, suitable for all kinds of printing and packaging of daily commodities.

Kraft paper: Natural and environmentally friendly, with va intage style, suitable for organic and natural products.

Cardboard: Provides a solid structure and is suitable for heavy-duty or high-grade merchandise packaging needs.

Corrugated: High strength and compression resistance, suitable for transport packaging and bulk goods.

Appearance Design of Custom Packaging Boxes

From colors to shapes, we provide you with a full range of custom designs to ensure that each packaging box perfectly matches your brand personality.

Logo Custom: Your brand identity, precise positioning in the market, and enhanced recognition.

Color Custom: Choose the color that matches your brand image to create a unique visual effect.

Shape Custom: Unique box design to meet creative needs and highlight product features.Whether it is the classic square, round, or triangle design.

Size Custom: Customized according to the size of the product to ensure that each item is protected most appropriately.

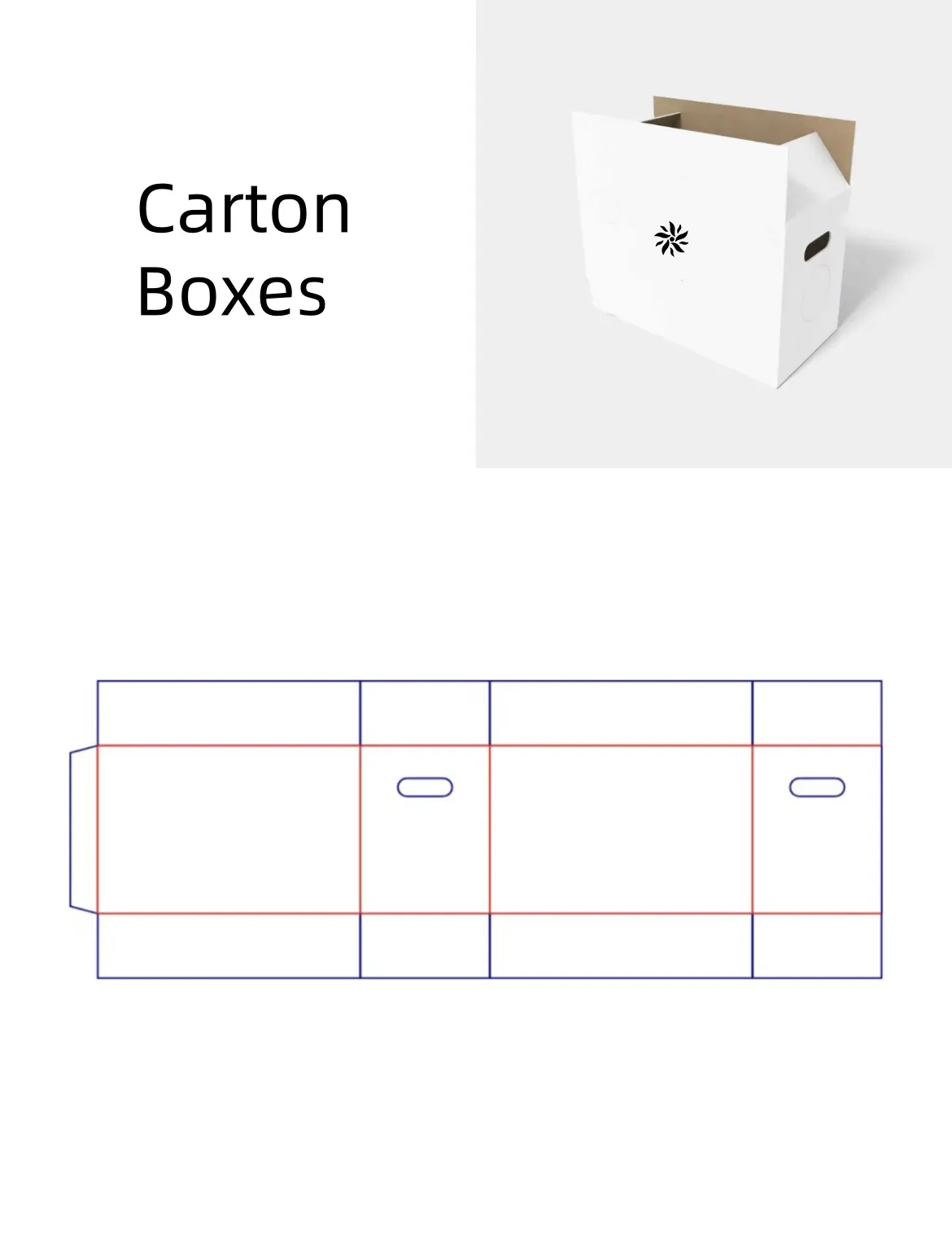

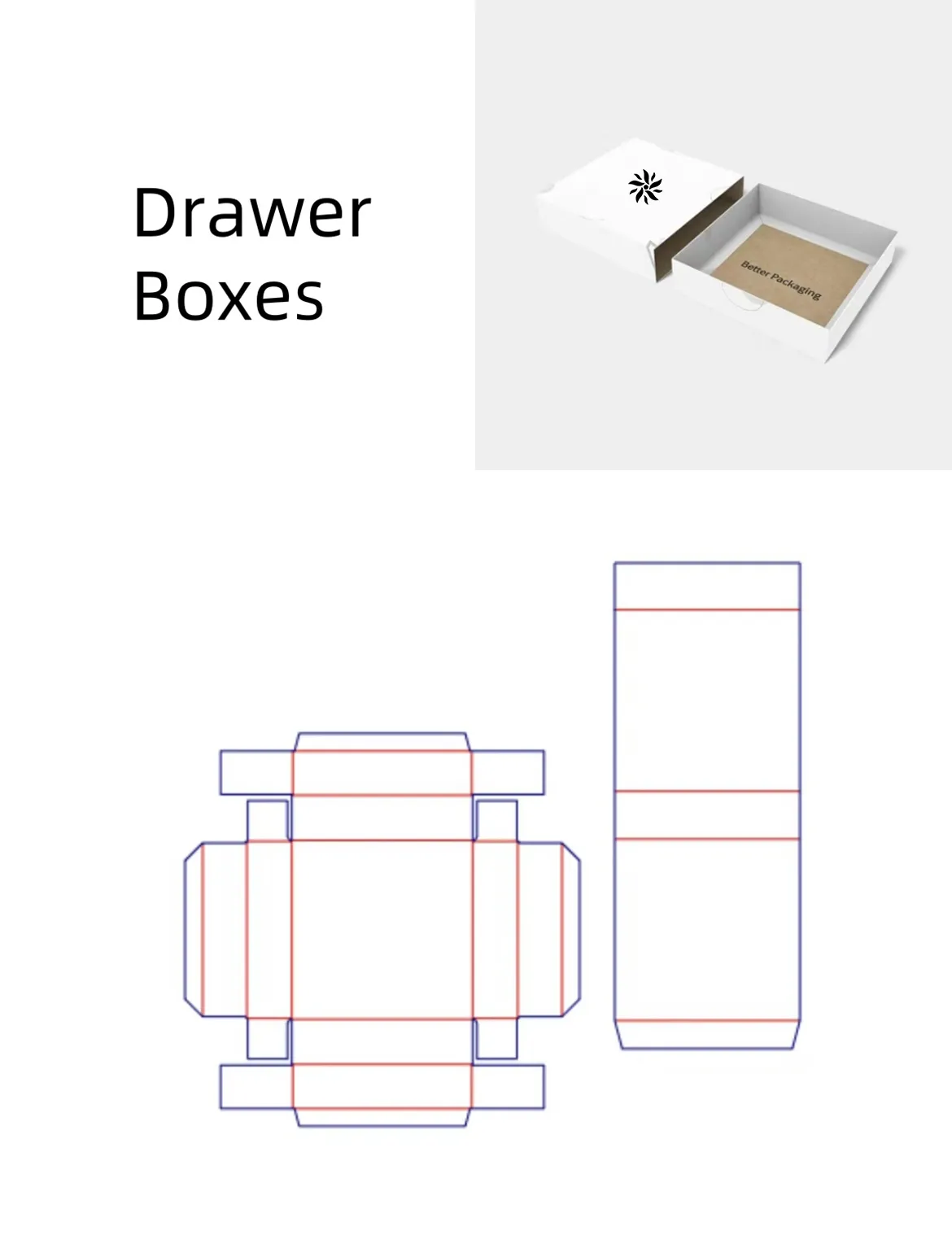

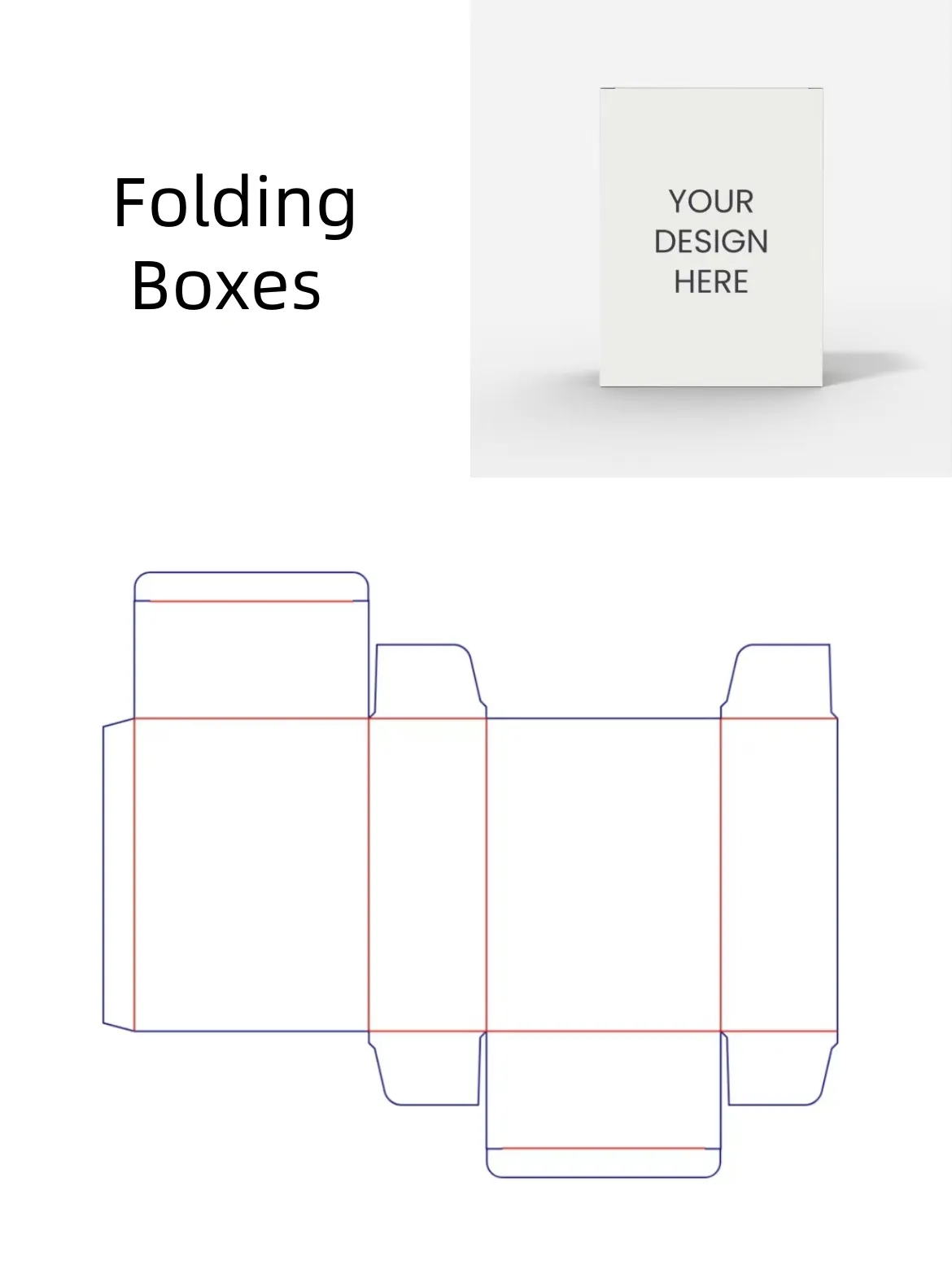

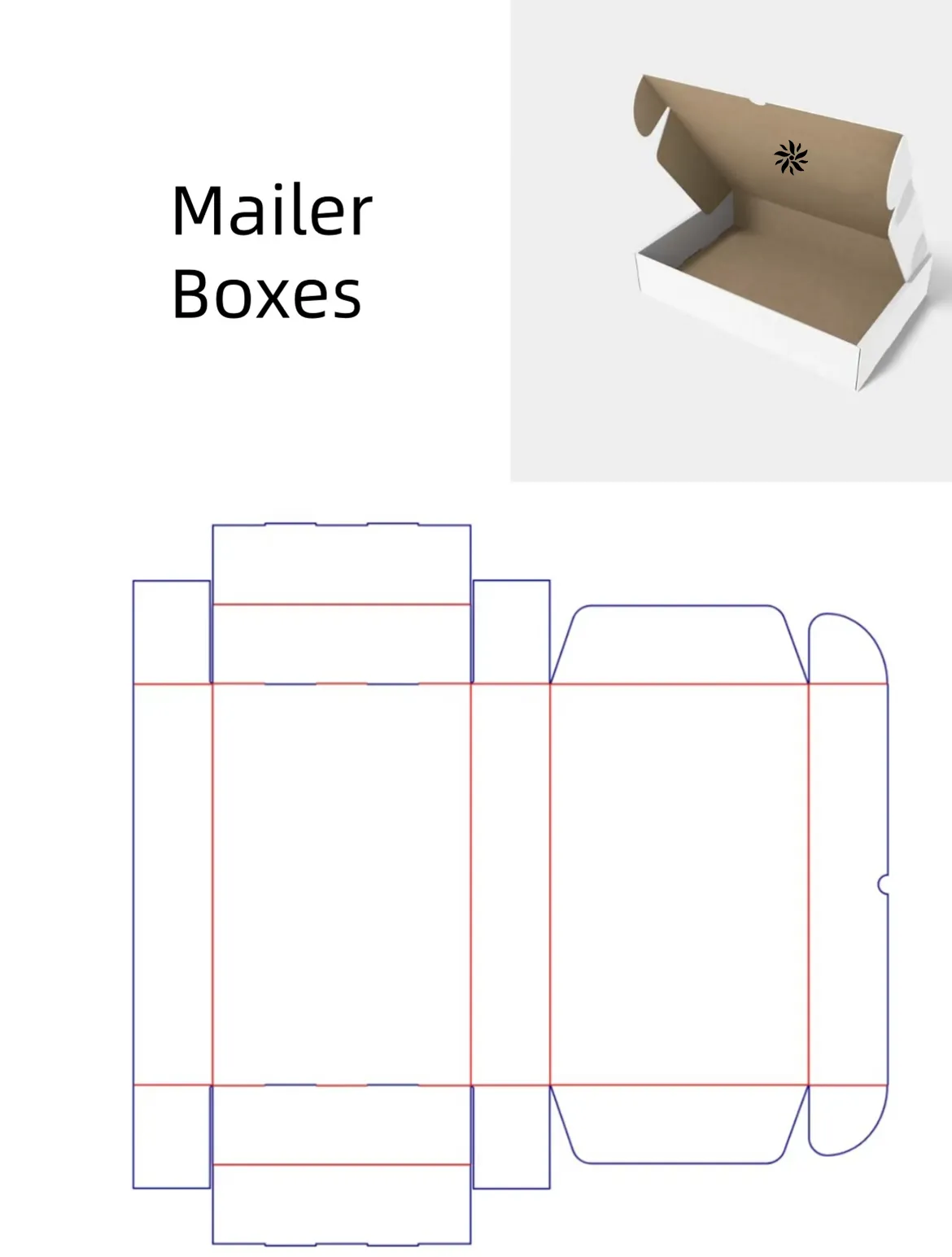

Customized Structure: Opening and closing methods (e.g. flap type, drawer type), hand-held design, transparent window, etc. to meet your packaging needs and enhance the user experience.

Printing Processes for Custom Printed Boxes

The surface treatment process enhances the beauty, texture and durability of the product boxes. Mainly used in printing and packaging materials.

UV Process: Using ultraviolet light to irradiate special inks or coatings that instantly dry and cure.

Hot Foil Stamping: By which gold or colored foils are transferred to paper and plastic material by applying heat application.

Embossing: This technique uses the mold to exert pressure on materials to produce concave and convex textures or patterns.

Combined Application: Three processes are combined to achieve aesthetic and fine-touch effects. Examples: UV + foil stamping, embossing + foil stamping, and UV + embossing.

Laminating Technology: Matte films or glossy films applied to the surface of printed matter or other materials.

Stickers and Labels for Customized Packaging

Enhance the professional and high-end feel of your packaging and increase interaction with consumers by customizing stickers and card sleeves.

Sticker and Label Custom: Customized stickers and labels of various patterns, sizes, and shapes according to requirements, enhancing brand recognition.

Cardholder Custom: Exquisite card packaging to enhance the packaging of gifts and high-end products and bring a unique user experience.

Ribbon: It is commonly used in gift and holiday packaging to enhance the decorative appearance.

Liners and Trays for Custom Packaging Boxes

Foam Lining: Used for high-grade packaging to protect fragile items, such as glass, ceramics, electronic products, etc.

EVA Liner: Soft and flexible, suitable for the protection of precision products.

Cardboard Liner: Economical and practical, can be custom shaped by cutting, molding, etc., suitable for general merchandise.

Velvet/Sponge Liner: Adds a sense of luxury to jewelry boxes, cosmetic boxes, etc. and protects the contents at the same time.

Shockproof Bubble Bags: used to prevent collision and vibration during product transport, especially suitable for fragile goods.

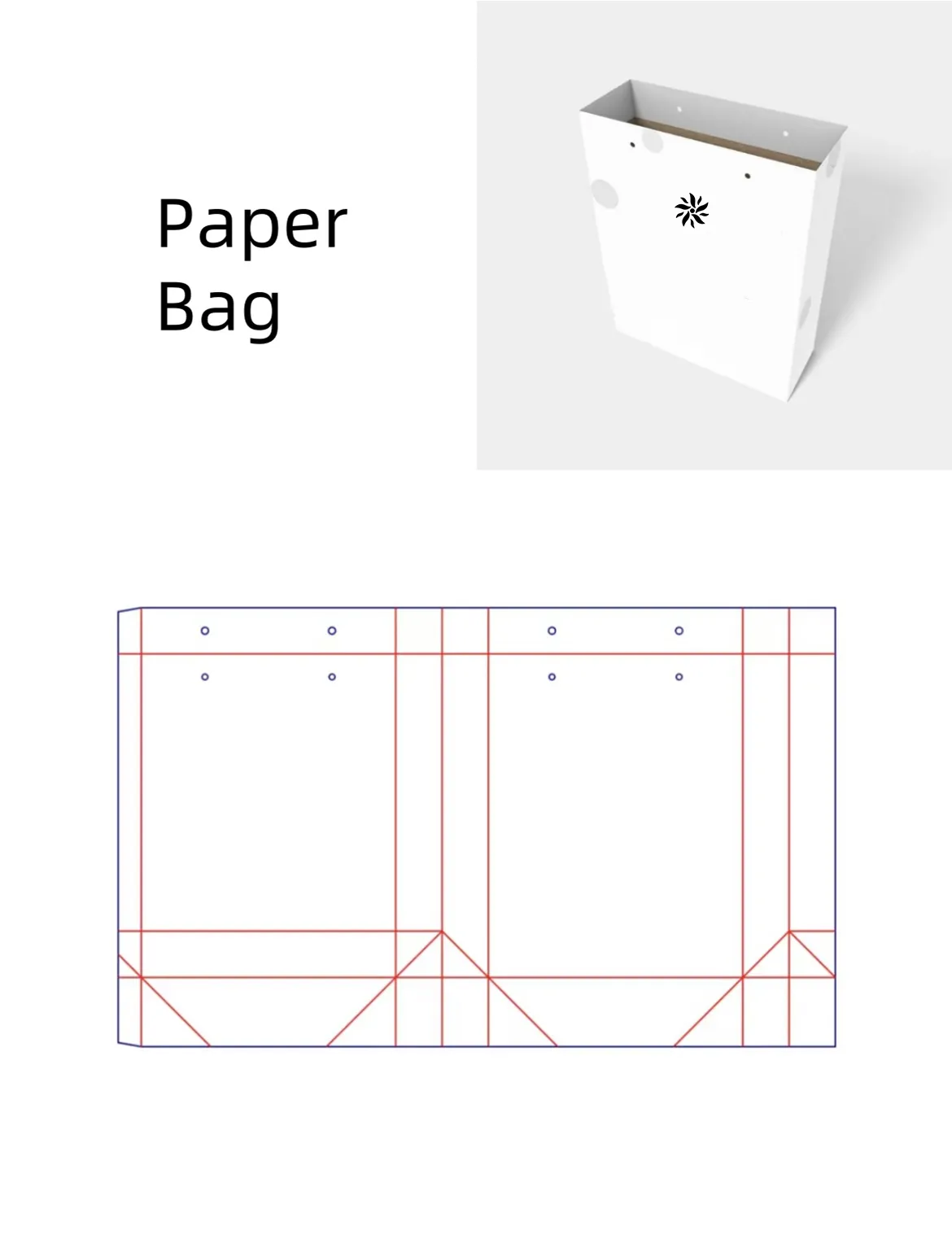

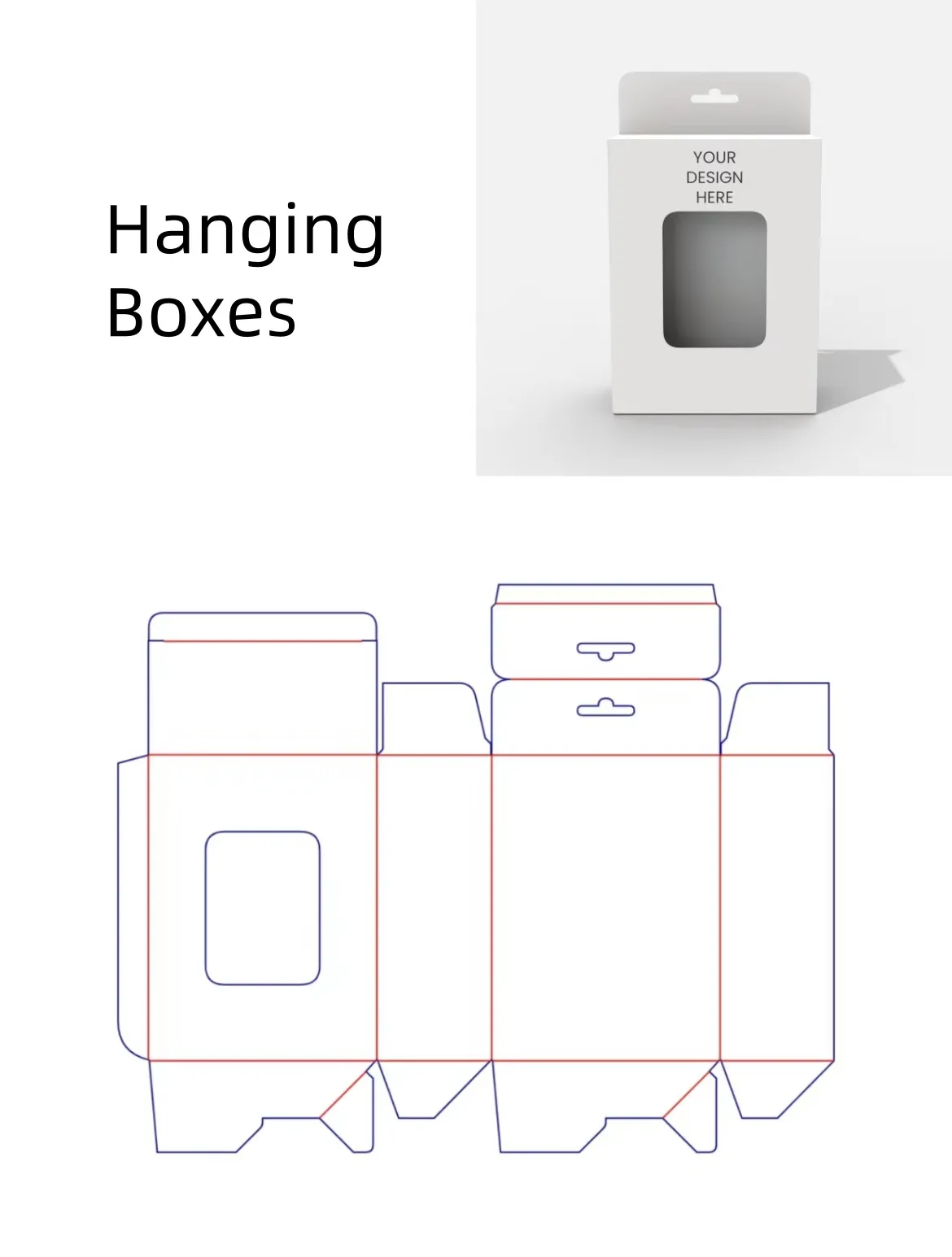

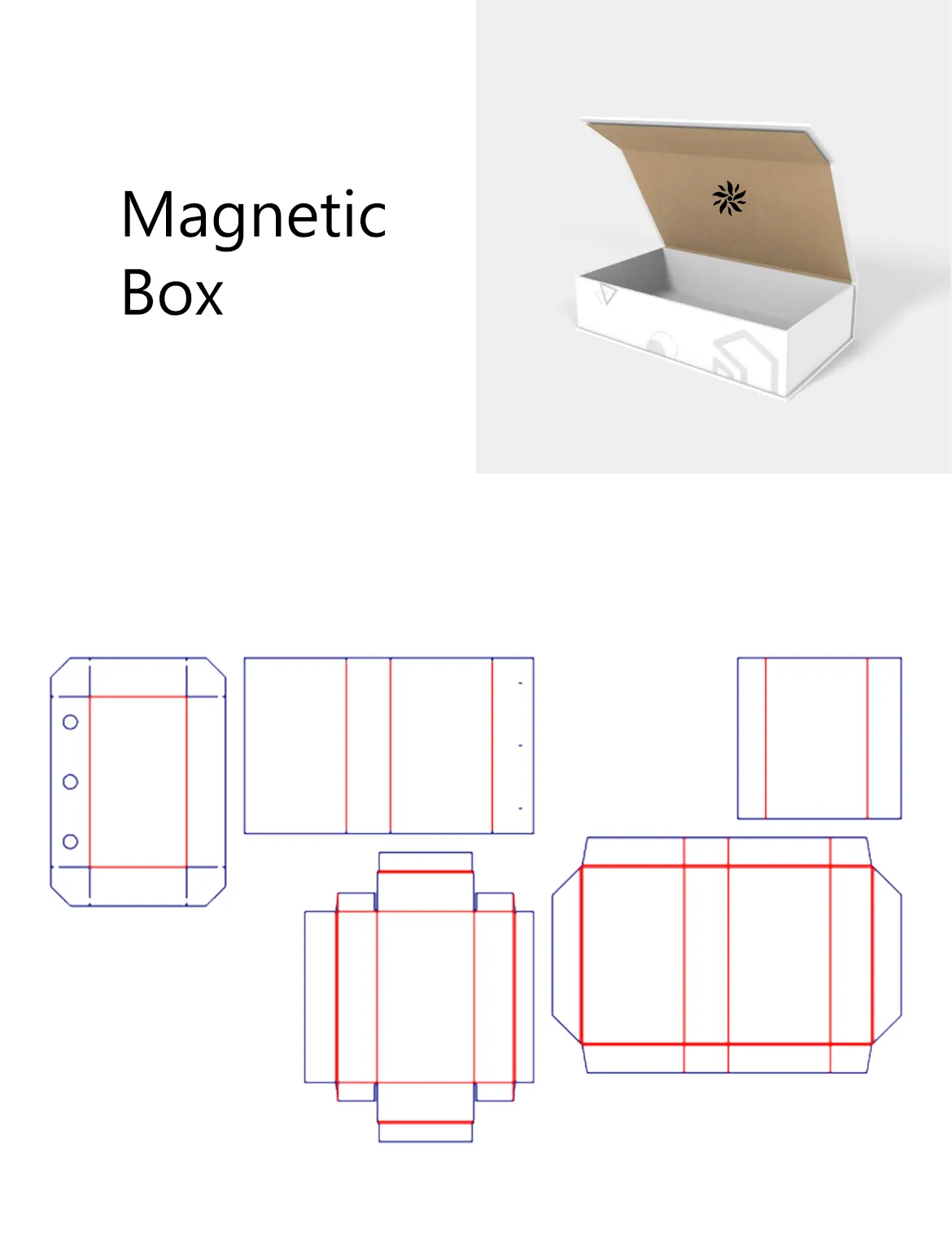

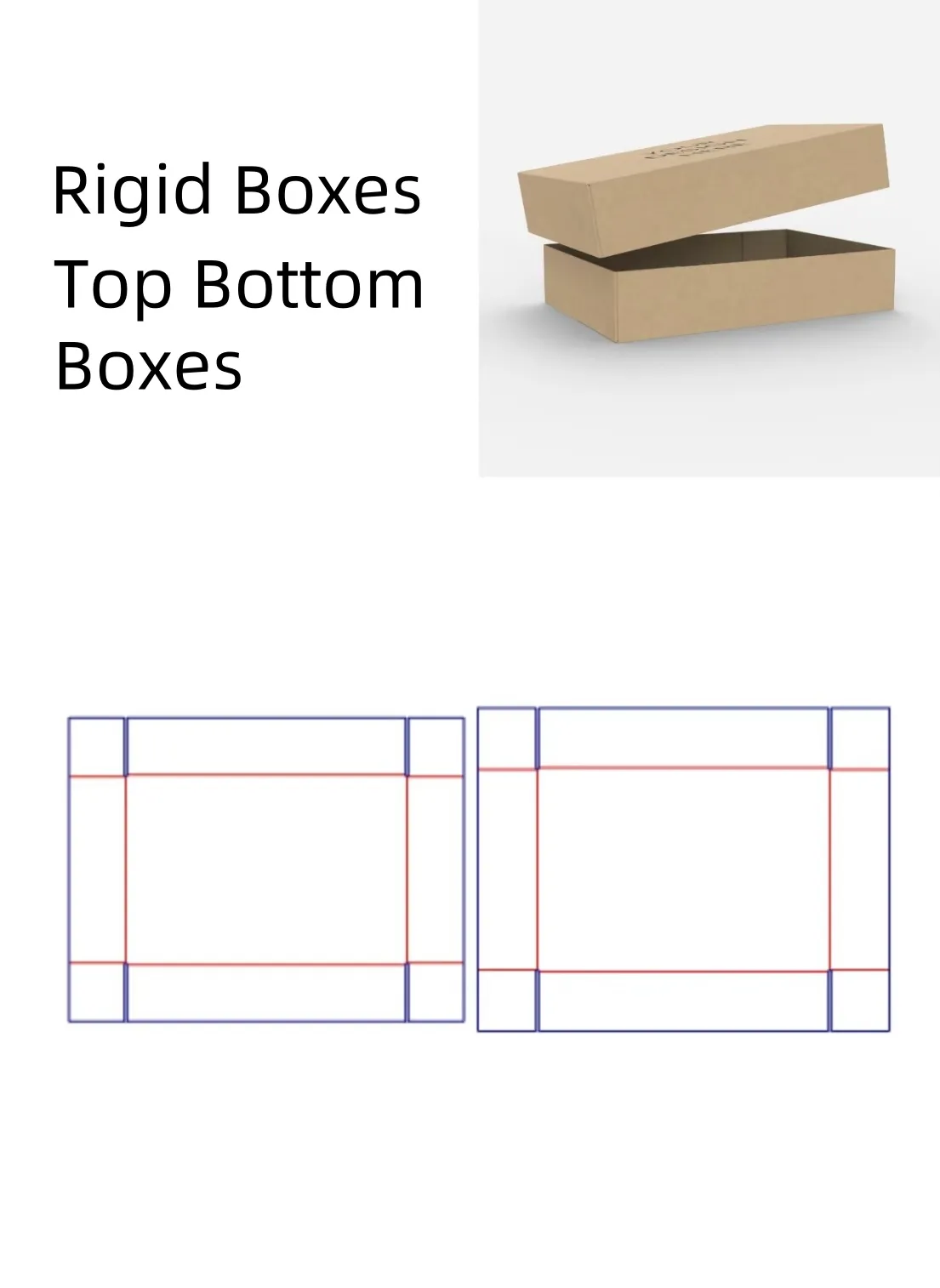

Customized Packaging Box Types

Custom Packaging Box Solution Process

Demand Communication

Design Solution

Sample Production and Adjustment

Production Confirmation

Capability Advantage of Yisheng Packaging Box Manufacturer

FAQs About Yisheng Custom Packaging Boxes

- How to customize packaging boxes?

You can provide your specific requirements by contacting our customer service team and we will provide you with a personalized solution.

- How long does it take to make samples of customized boxes? Are stock samples free?

Our sample-making lead time is 1-5 working days (depending on the complexity). For stock samples, we offer up to 10 free samples. The shipping time is 3-5 days and you only need to pay for the shipping cost.

- What is the minimum order quantity?

Depending on our production cost and efficiency, the minimum order quantity is 1 case for regular products and 1,000 pieces for customized products.

- Does Yisheng support expedited production?

Yisheng can support expedited production! Please contact customer service to communicate expedited needs, we will prioritize the production line and quote extra.

- What design file formats do we accept?

We support the following formats: CorelDraw (.cdr), Adobe Illustrator (.ai), InDesign (.indd), PDF (editable layers), Photoshop (.psd), and it is recommended that you provide the source files to ensure printing accuracy.

- Do you provide after-sales service?

Yes, we offer a comprehensive after-sales service. Our after-sales team will provide timely support and assistance. If you encounter any problems, please feel free to contact.If you have any problems, please feel free to contact us.